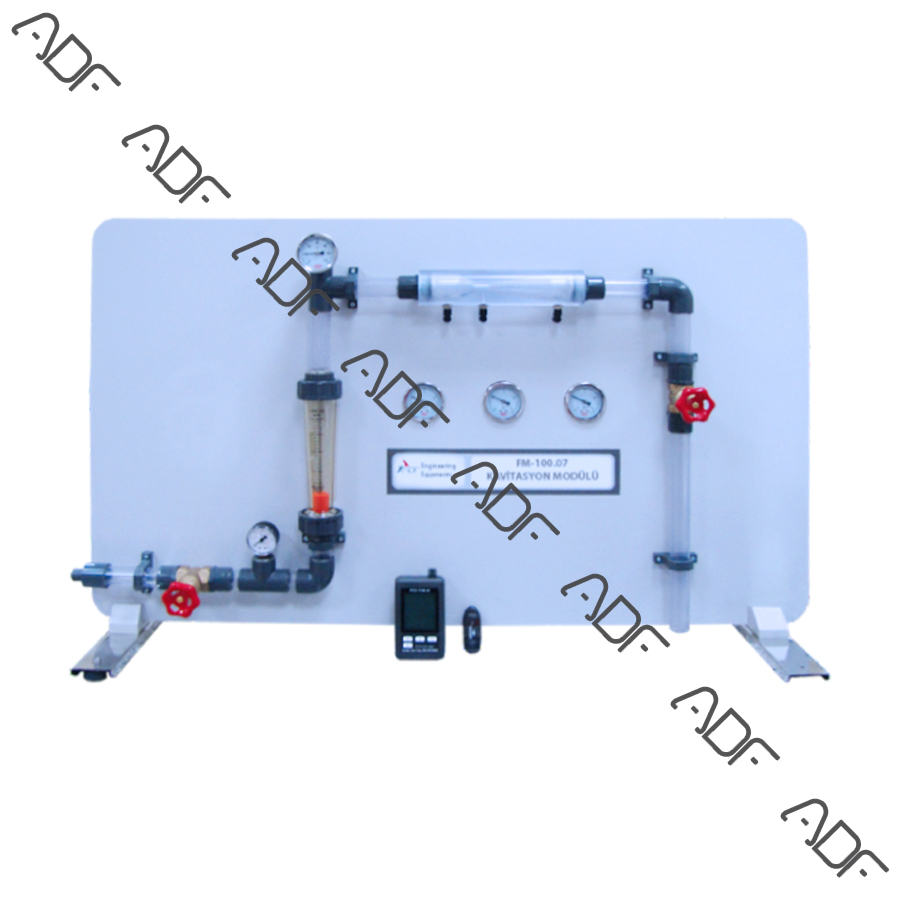

Cavitation Module

FM-100.07

Cavitation refers to the formation of vapor bubbles in flowing fluids due to strong low pressure. As the flow velocity increases, the static pressure of the fluid falls to the vapor pressure and leads to the formation of vapor bubbles. The bubbles are carried along by the flow and implode if, with decreasing velocity, the static pressure rises above the vapor pressure of the fluid.

FM 100.07 is suitable for the demonstration of cavitation processes using the example of a Venturi nozzle. Pressure energy is converted into kinetic energy and vice versa in the Venturi nozzle. Vapor bubbles form in the narrowest cross-section. To visualize the flow processes the experimental unit includes a Venturi nozzle made of transparent plastic. There are three pressure measuring points on the Venturi nozzle: at the inlet, at the narrowest point and at the outlet. The input pressure can be adjusted via a pressure reducing valve.

The flow rate and the pressures can be adjusted via two ball valves which are located at the inlet and outlet of the pipe system. The pressure distribution within the Venturi nozzle is shown on three manometers. The flow can be read off a rota meter. The temperature is measured directly upstream of the Venturi nozzle and is displayed on the thermometer.

Specifications

- Investigation of cavitation processes in a Venturi nozzle

- Venturi nozzle with 3 pressure measuring points

- Adjustment of the flow rate via ball valves

- Pressure reducing valve, adjustable

- Thermometer for measuring the temperature

- Flow measurement using rota meter

- Manometer for displaying the pressure curve in the Venturi nozzle Technical Details

- Pressure reducing valve

- 0,5…2bar

- Up to 70°C

- Transparent Venturi nozzle

- Cross-section of flow

- Inner diameter: 18mm

- Contraction: 10,5°

- Output cross-section

- Inner diameter: 18mm

- Enlargement: 4°

- Narrowest cross-section

- Inner diameter: 3,5mm

Measuring ranges:

- Pressure: -1…1,5bar

- Temperature: 0…60°C

- Flow rate: 0…1000L/h

Required for operation

- Water connection: 4 bar, drain